High-temperature ceramic materials for precision casting

Publish Time:

2025-03-17

Precision casting is a general term for processes that obtain castings with precise dimensions. Compared to traditional sand casting, precision casting produces castings with more precise dimensions and better surface finish. It includes: investment casting, ceramic mold casting, metal mold casting, pressure casting, and lost-wax casting. Ceramic materials involved in precision casting mainly include: ceramic filters, ceramic crucibles, and ceramic pouring cups.

Precision casting is a general term for processes that produce castings with precise dimensions. Compared to traditional sand casting, precision casting produces castings with more precise dimensions and better surface finish. It includes: investment casting, ceramic mold casting, metal mold casting, pressure casting, lost-foam casting, etc. The ceramic materials involved in precision casting mainly include: ceramic filters, ceramic crucibles, ceramic pouring cups, etc.

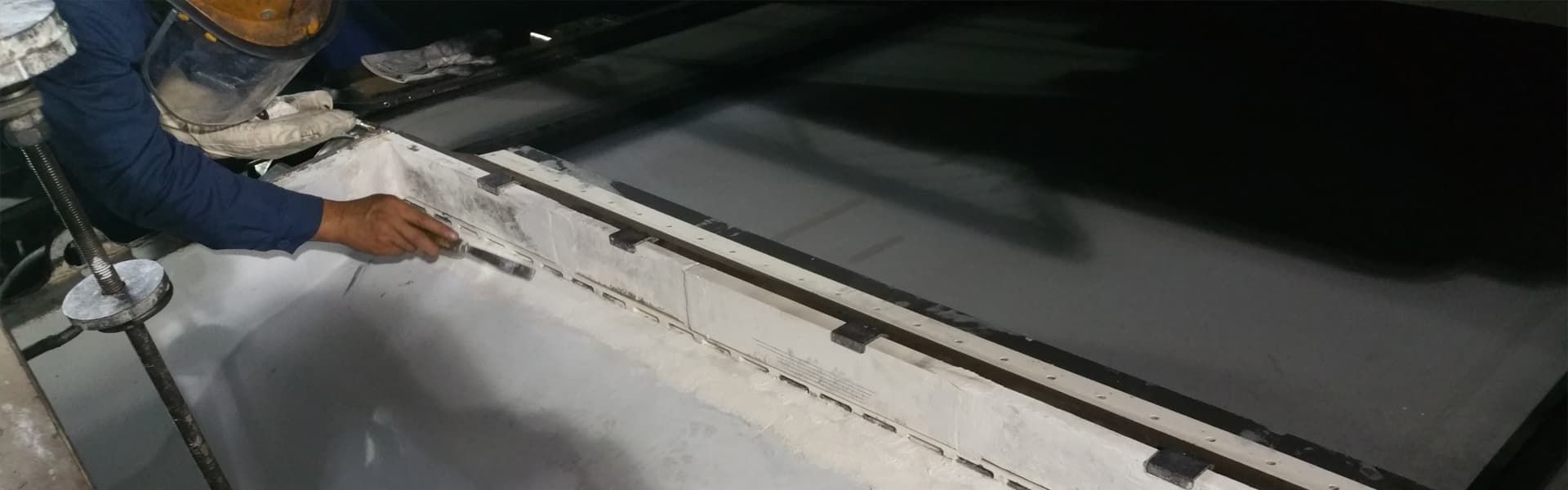

Molten Stone Foam Ceramic Filter

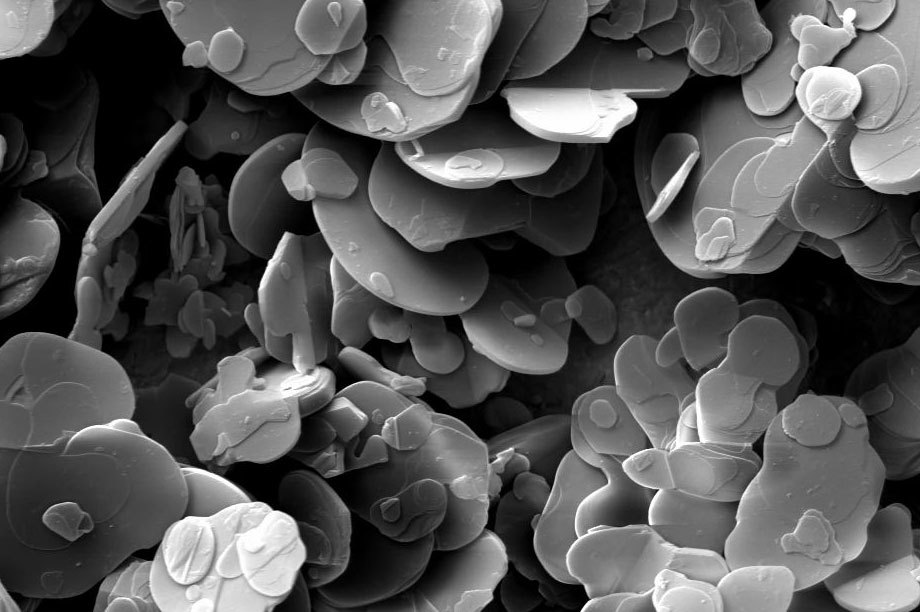

Ceramic filters are mainly used for metal casting filtration in the foundry industry. Suitable for cast steel and large cast iron parts, they effectively remove large inclusions from the molten metal, adsorb small particulate impurities, and improve the mechanical properties of the castings. Applicable to all steel grades, including carbon steel, stainless steel, cobalt-based, and nickel-based high-temperature alloy steels.

Foam ceramic filters are used to filter out solid slags such as metal oxides contained in molten metal during precision casting, thereby improving the quality and yield of castings. Therefore, the use of foam ceramic filters has promoted technological advancements in the foundry industry.

1. Common Specifications

● Pore Size: 10-20 PPI;

● Size: Customizable according to requirements;

● Edging Requirements: 1mm, 2mm, and 3mm fiber cotton can be customized.

2. Index Parameters

3. Features & Advantages

● Good temperature resistance, long-term use at 1700℃;

● High purity, stable material quality;

● Uniform pore structure, high porosity, stable flow rate when molten metal passes through;

● Excellent impact and stamping resistance.

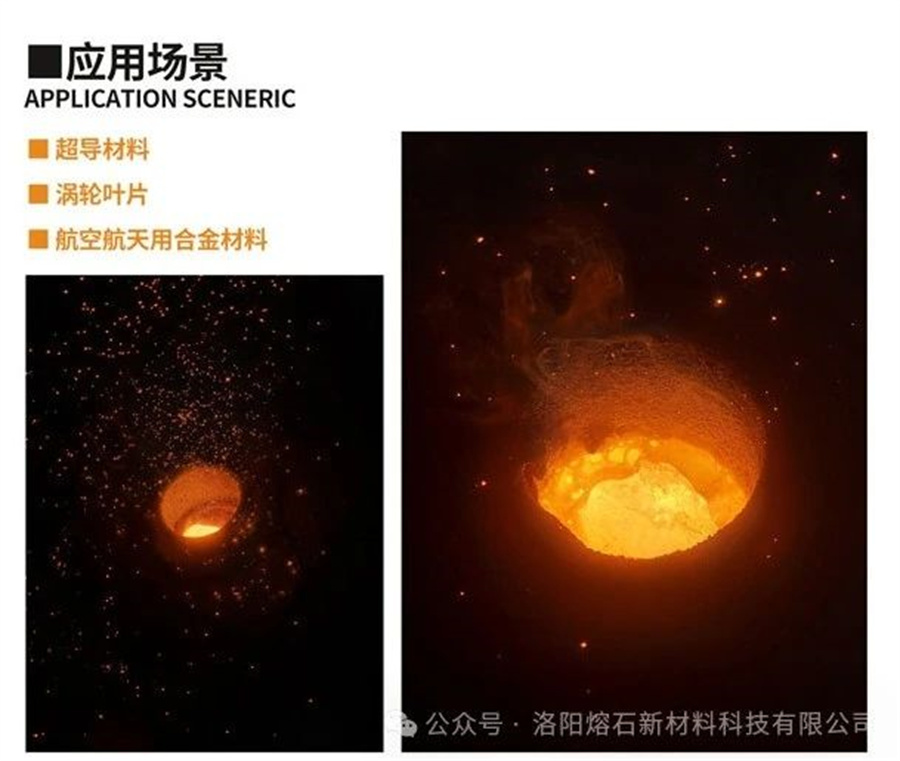

Molten Stone Special Alloy Melting Crucible

Special alloy melting crucibles are widely used in the melting of aerospace high-temperature alloys, superconducting alloys, titanium alloys, stainless steel, etc., ensuring efficient and stable production processes and providing support for high-quality production for customers. The performance of this crucible is comparable to imported materials. It can be used stably at high temperatures of 1600℃ for a long time and has the characteristics of being not easy to crack, not easy to produce slag, high strength, and excellent thermal shock stability. Using in-situ net-shape forming technology ensures dimensional accuracy and structural integrity.

1. Features & Advantages

● Using in-situ net-shape forming, uniform composition, high density;

● High purity, excellent resistance to high-temperature alloy corrosion;

● Excellent thermal shock stability, can be reused multiple times without defects;

● Good temperature resistance, long-term use at 1600℃.

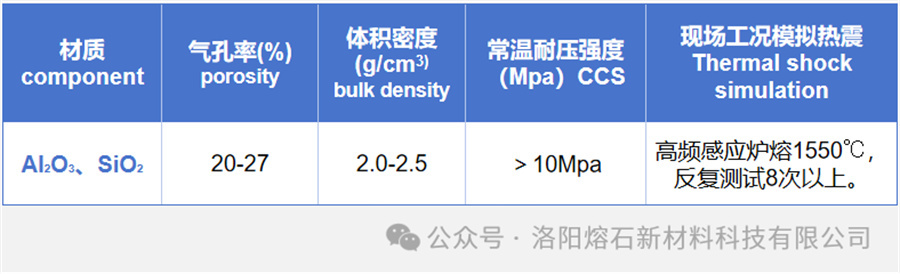

2. Index Parameters

It has good thermal shock stability, heat impact resistance, and is easy to clean and maintain, focusing on extending service life, reducing replacement frequency, and thus reducing overall costs.

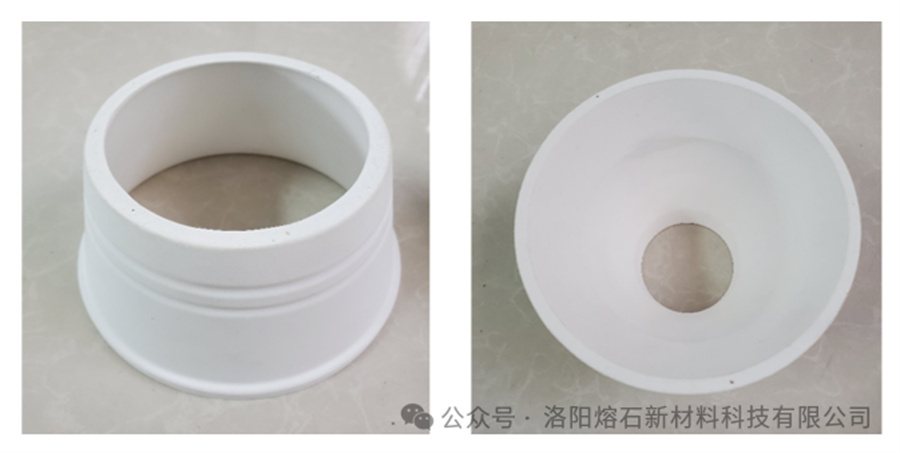

Molten Stone Ceramic Pouring Cup

Applicable to all steel grades, including carbon steel, stainless steel, cobalt-based, and nickel-based high-temperature alloy steels. Especially for casting complex shapes, high precision, and high-performance metal parts. Through precise design, it can control the flow rate of molten metal, prevent bubbles and inclusions from entering the casting, and ensure the quality of the casting.

1. Features & Advantages

● Good high-temperature stability, no shedding, smooth inner and outer walls;

● Good thermal shock resistance, resistance to rapid temperature changes;

● High strength, erosion resistance;

● Slag erosion resistance, resistance to high-temperature melt corrosion.

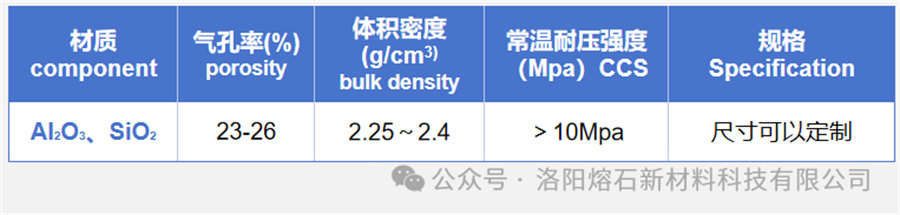

2. Index Parameters

Keywords:

Learn More Cases

Based on the innovation in the high temperature industry technology field, we constantly explore to solve the needs of high-end high temperature resistant materials and their application fields.