Vertical direct-chill flat-rolled casting solution

Publish Time:

2025-03-17

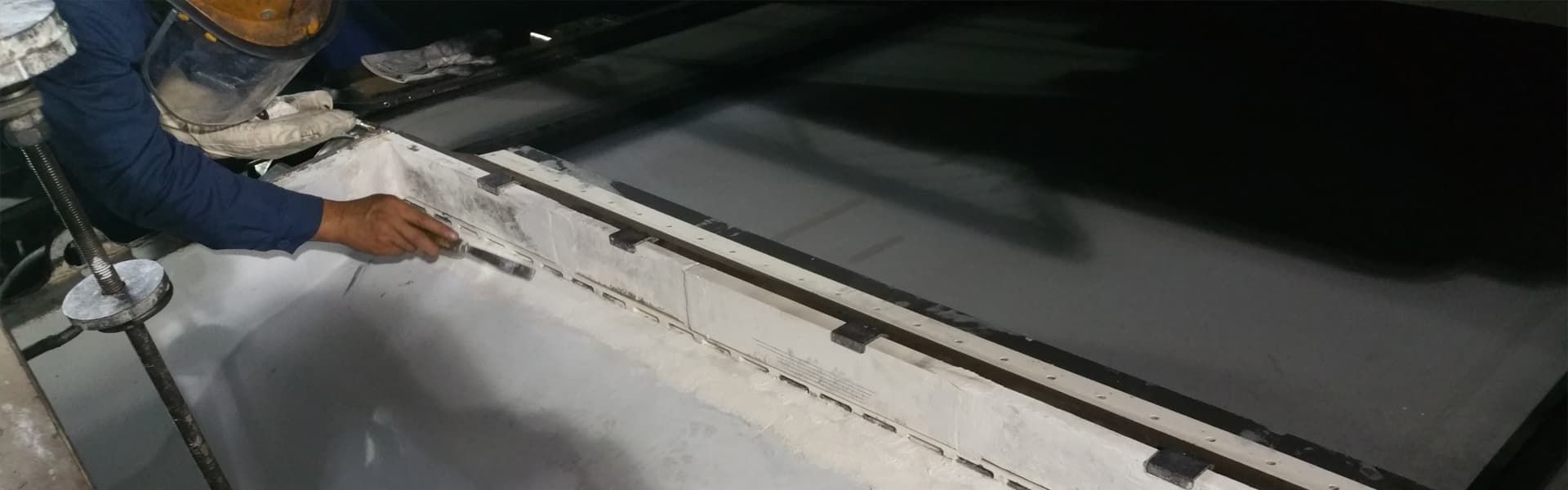

The vertical direct-chill casting process for flat billets involves various consumables. For a long time, Rongshi Technology has been providing such consumables to flat billet manufacturers, and all consumables use suitable materials. Rongshi can also provide customers with complete solutions for aluminum liquid conveying, filtration, and safe production.

The vertical direct-chill casting process for flat billets involves various consumables. For a long time, Longshi Technology has been providing such consumables to flat billet manufacturers. All consumables use suitable materials. Longshi can also provide customers with complete solutions for aluminum liquid conveying, filtration, and safe production.

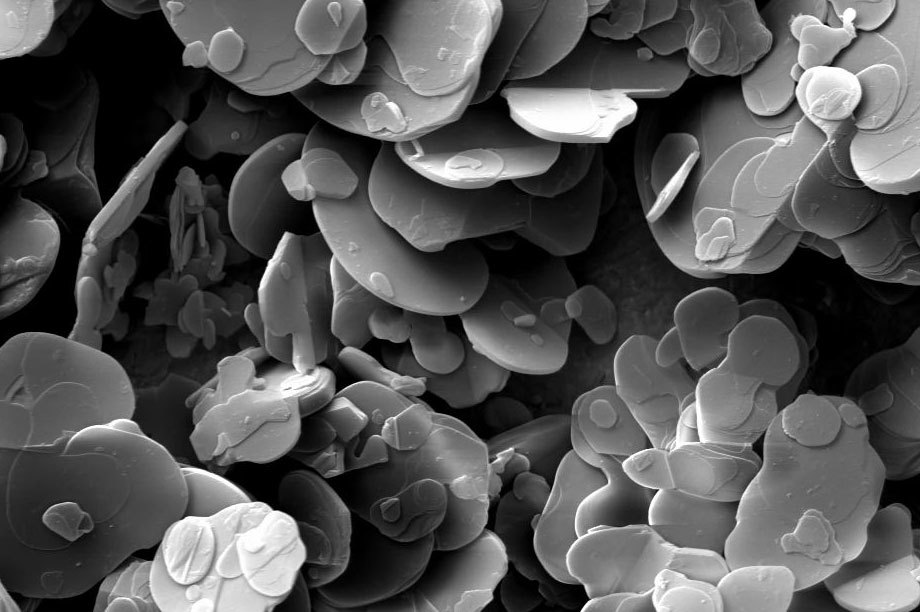

Boron Nitride Coating

Boron nitride coating is an inert inorganic high-temperature lubricating material. It is non-sticky and does not penetrate molten metal liquid. It can completely protect the surface of refractory materials or ceramic containers in direct contact with molten aluminum, magnesium, zinc alloys, and slag, playing a role in high-temperature resistance, anti-adhesion, and oxidation resistance, thereby improving casting efficiency, reducing the defect rate, and extending the service life of the mold. In addition, boron nitride coatings can also be used in the smelting and casting of aluminum alloys to protect the metal surface, prevent oxidation and corrosion, and improve the wear resistance and fatigue resistance of aluminum alloys.

● Ap FDI type boron nitride lubricating coating concentrate

● Al FDI type boron nitride lubricating coating concentrate

● AP AL direct-use type boron nitride lubricating coating

Repair agent

Ceramic fiber sealant is made from high-quality aluminosilicate fiber as the main raw material and can be used in the aluminum melting and casting industry for repairing refractory materials, sealing the interfaces of refractory materials, and kiln construction. RSH type fiber adhesive is known for its excellent anti-shrinkage and convenient construction characteristics. This type of product has selective adhesion, strong adhesion to the surface of inorganic non-metallic substrates, but shows non-sticky lubricity to technical tools such as trowels and shovels used in construction. This makes it easier for operators to smooth and hang the mud during construction. Its fine, smooth, and non-corrosive texture is also an environmentally friendly characteristic of this product.

● Hec-800

● Hec-1000

● Hec-1400

Distribution trough

A complete trough system solution can be designed according to customer needs. This includes converter troughs, transfer ladles, casting troughs, and distribution troughs. Matching trough products, heating systems, and trough gates (slag barrier/flow control) are also provided.

Filtration

● Deep bed grid

● Alumina filter media (alumina balls, gravel)

● Filter box lining

Flow control device

Made by casting with high-quality raw materials. Used to regulate the flow rate of aluminum liquid. The product has high strength, is resistant to scouring, has a long service life, is not easy to peel, and has stable flow control.

● Plug rod

● Bottom casting tube

Slag barrier ring

The slag barrier ring effectively inhibits the formation of oxide skin at the front end of the flat billet casting, improves the surface quality and yield of the flat billet, and is particularly suitable for the production of easily oxidized alloys. More durable thin-walled slag barrier rings are made to adapt to small spaces and can be placed in deeper positions, making the slag barrier ring more widely applicable.

Luoyang Longshi New Materials Technology Co., Ltd. specializes in the production, research and development, and sales of high-end boron nitride coating products, light-weight heat-insulating functional ceramics for melting and casting, and high-strength functional heat-insulating materials. The products are of good quality and excellent protective performance, and are favored by customers at home and abroad. Longshi not only provides customers with high-quality products but also provides professional technical solutions to meet customers' differentiated application needs and provide customers with high-quality services.

Keywords:

Learn More Cases

Based on the innovation in the high temperature industry technology field, we constantly explore to solve the needs of high-end high temperature resistant materials and their application fields.