Applications of boron nitride coatings

Publish Time:

2025-03-17

With the continuous improvement of aluminum alloy casting technology, the quality of aluminum alloy products has also been continuously improved. Among them, coatings play a crucial role. They form a protective layer on the surface of casting tools, improving the corrosion resistance of casting tools, reducing or even avoiding contact between the alloy liquid and the casting tools, thereby effectively avoiding the corrosion of the casting tools by the alloy liquid and the contamination of the alloy liquid by the casting tools, improving the quality of castings, and ensuring the performance of the aluminum alloy.

As aluminum alloy casting technology continues to improve, the quality of aluminum alloy products is also constantly improving. Coatings play a crucial role, forming a protective layer on the surface of casting tools, improving the corrosion resistance of the casting tools, reducing or even avoiding contact between the alloy liquid and the casting tools, thus effectively avoiding the corrosion of the casting tools by the alloy liquid and the contamination of the alloy liquid by the casting tools, improving the quality of castings, and ensuring the performance of the aluminum alloy.

Application of Boron Nitride Coating

1. Boron nitride coating is an inert inorganic high-temperature lubricating material. It is non-sticky and does not penetrate into molten metal liquid. It can completely protect the surface of refractory materials or ceramic containers that are in direct contact with molten aluminum, magnesium, zinc alloys and slag, playing a role in high-temperature resistance, anti-adhesion, and anti-oxidation, thereby improving casting efficiency, reducing the defect rate, and extending the service life of the mold. In addition, boron nitride coating can also be used in the smelting and casting process of aluminum alloys to protect the metal surface and prevent oxidation and corrosion, while also improving the wear resistance and fatigue resistance of the aluminum alloy.

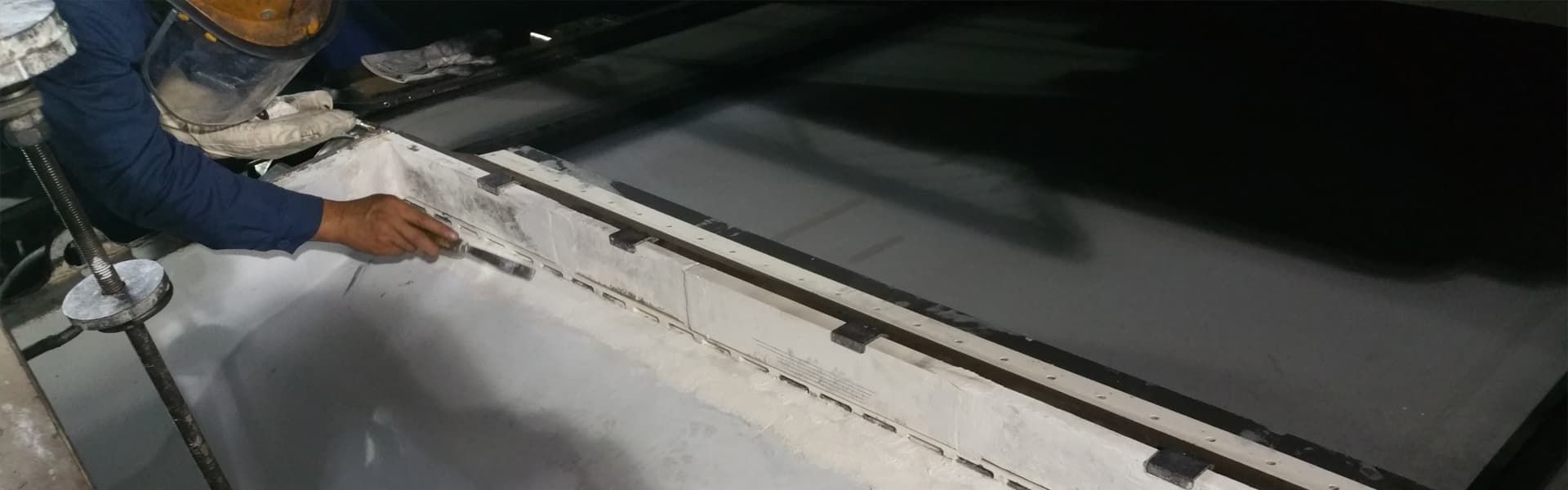

2. Boron nitride coatings are widely applied to the surfaces of casting runners, distribution runners, transfer plates, sleeves, degassing equipment linings, filter boxes, casting nozzles, slag spreaders, and ladles, protecting molds, resisting corrosion and extending the service life of refractory materials. At the same time, during production, it prevents fine impurities from penetrating into the aluminum liquid, causing secondary pollution, and greatly improving product quality.

3. It is the preferred choice for customers with higher melting and casting requirements or higher requirements for cast products, and it is a necessary product for the production of military-grade products.

Characteristics of Rongshi Boron Nitride Coating

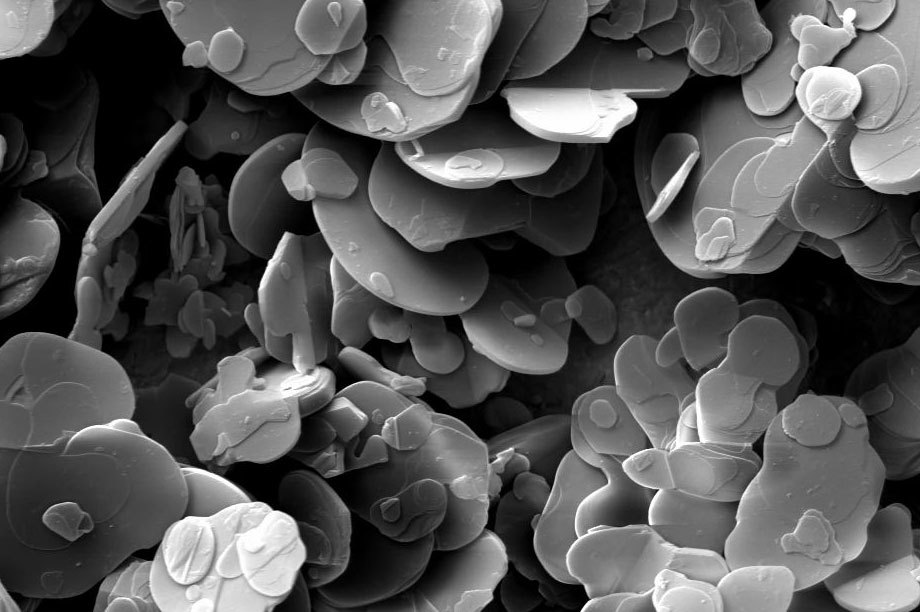

1. Using high-crystallinity high-purity boron nitride powder as raw material, it has excellent lubricity and oxidation resistance;

2. Rongshi boron nitride has good electrical insulation, mechanical stability, thermal conductivity, and chemical inertness;

3. It has high non-wetting characteristics with copper, aluminum non-ferrous metals, and melts such as glass;

4. It remains stable at 1000°C in air and maintains excellent performance at 2300°C under a protective atmosphere;

5. This series of coating products use deionized water as a solvent and do not contain harmful impurity ions;

6. The coating system is weakly acidic or alkaline and will not harm the surrounding environment, and it is an environmentally friendly product.

Rongshi Boron Nitride Coating Technical Parameters

Category | Concentrated Coating | Ready-to-use Type | |||

| AP FDI | AL FDI | AL C180 | AP AL | |

Color | White/Blue | White/Blue | White/Blue/Gray | White/Blue/Gray | |

Dilution Ratio | 1:5~7 | 1:5~7 | 1:4~5 | 1:3 | |

Boron Nitride Effective Content | >75% | >85% | >70% | >70% | |

Free Boron Content | <0.06% | <0.06% | <0.06% | <0.06% | |

Solid Content | 35-37% | 32-35% | 30-35% | 23-25% | |

pH Range | 7~8 | 3~4 | 5~6 | 5~6 | |

Binding System | Amorphous Silicon Type | Amorphous Aluminum Type | Amorphous Aluminum Type | Amorphous Aluminum Type | |

Solvent | Water | Water | Water | Water | |

| Oxidizing Atmosphere | 1000℃ | 1000℃ | 1000℃ | 1000℃ |

Vacuum Atmosphere | 1500℃ | 1500℃ | 1500℃ | 1500℃ | |

Reducing Atmosphere |

| 1800℃ | 1800℃ | 1800℃ | |

Luoyang Rongshi New Materials Technology Co., Ltd. specializes in the production, research and development, and sales of high-end boron nitride coating products, lightweight heat-insulating functional ceramics for casting, and high-strength functional heat-insulating materials. Products are of good quality, with excellent protective performance, and are well-received by customers at home and abroad. Rongshi not only provides customers with high-quality products but also provides professional technical solutions to meet customers' differentiated application needs and provide customers with high-quality services.

Keywords:

Learn More Cases

Based on the innovation in the high temperature industry technology field, we constantly explore to solve the needs of high-end high temperature resistant materials and their application fields.

Index/Model

Index/Model