Molten rock foam ceramic filter

Publish Time:

2025-03-17

In the metal smelting process, inclusions originate from various sources, including surface oxide films, eroded refractory materials from the furnace, and insoluble impurities such as carbides.

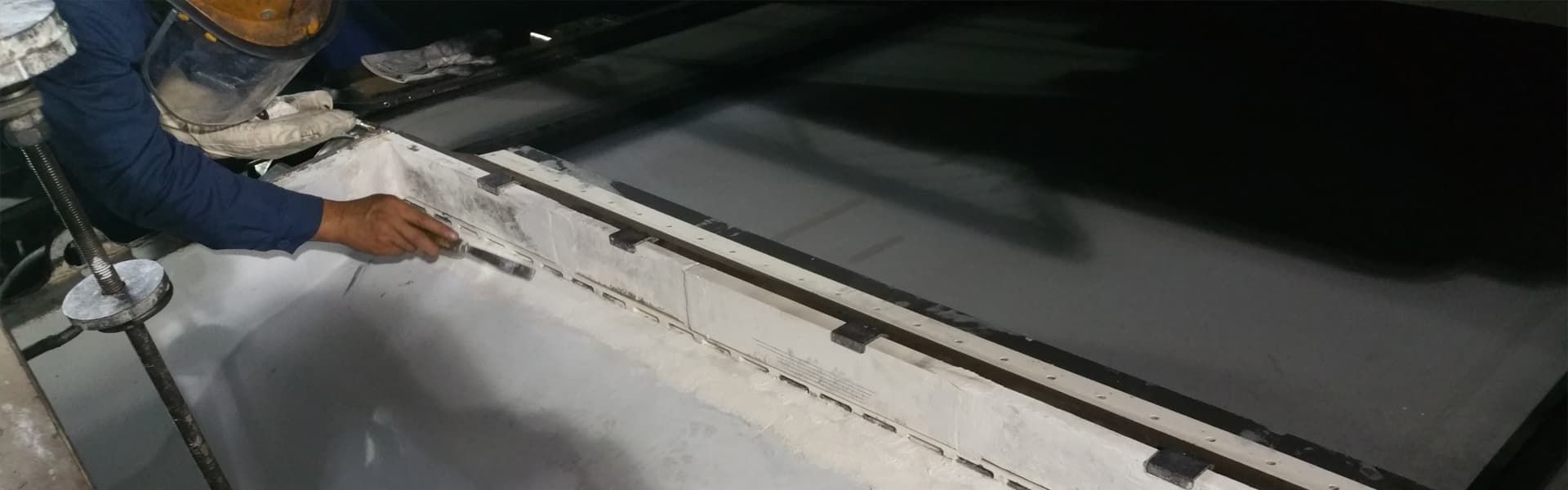

In the metal smelting process, inclusions originate from various sources, including surface oxide films, eroded refractory materials from furnaces, and insoluble impurities such as carbides. If not filtered, these impurities may be trapped in the solidified metal. Therefore, similar to online degassing, foam ceramic filters are a necessary supplement to in-furnace metal treatment. The presence of inclusions in molten metal liquids adversely affects the quality and performance of metal products in various ways, particularly detrimental to the fatigue strength of aluminum alloys. Multiple smelting processes such as melting, alloying, and casting can lead to various non-metallic inclusions in the liquid, which may be the primary source of defects in the final product.

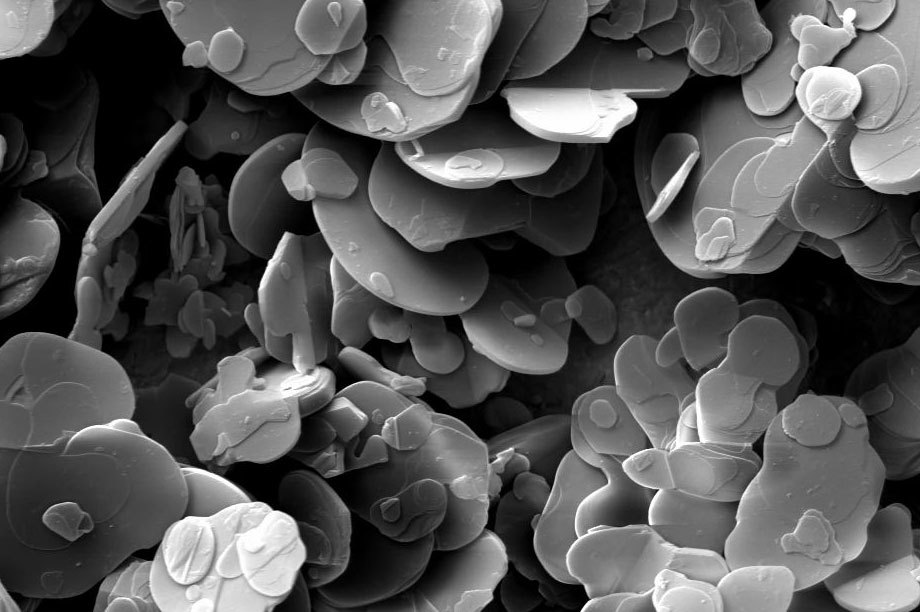

1. Foam ceramic filter plates have four filtration and purification mechanisms

(1) Mechanical sieving (interception): Removal of large-particle inclusion oxides.

(2) Filter cake mechanism: Filtration of small-particle inclusion oxides.

(3) Deep filtration (chemical adsorption): Adsorption of fine inclusions.

(4) Rectification mechanism: Causes the fluid flow to change from turbulent flow to laminar flow, preventing the formation of eddies.

2. Functions of the filter

(1) Filters slag, reducing the harm of slag to castings.

(2) Filters out bubbles from the molten metal.

(3) Rectifies the flow of molten metal from turbulent to laminar flow, reducing secondary oxidation and gas absorption, and improving casting performance.

3. Principles of filter use

(1) The filter should be placed as close to the cavity as possible and can be placed at any angle.

(2) The gating system design should be simple and other slag-blocking measures may not be considered. This improves the utilization rate of the sand mold and the process yield.

(3) The working area of the filter should be 4-6 times the restricted flow cross-section of the gating system to ensure that the pouring speed is not affected.

(4) Select according to the type of casting alloy and pouring temperature; do not use at temperatures exceeding the limit.

(5) Choose the appropriate pore size to achieve the true filtering effect.

(6) Do not use the filter to control the pouring speed.

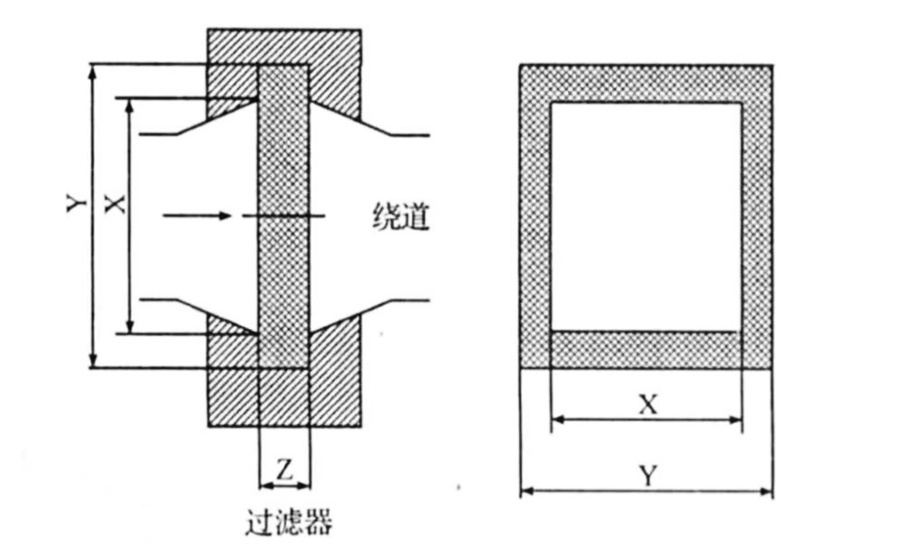

4. Filter placement

Filters are placed in the gating system of the casting. The gating system is the channel in the mold that guides the liquid metal into the cavity. Generally, the filter is placed in:

(1) The upper or lower end of the sprue;

(2) In the runner;

(3) In the pouring cup.

5. Size and structure of the filter placed in the gating system

6. Filter size, filtration speed, and filtration capacity

Size | 10ppi | 20ppi | ||||||

Filtration flow rate | Filtration speed | Filtration flow rate | Filtration speed | |||||

Gray iron | Ductile iron | Gray iron | Ductile iron | Gray iron | Ductile iron | Gray iron | Ductile iron | |

30×30×22 | 30 | 15 | 2 | 1 | 20 | 10 | 1.5 | 0.8 |

50×30×22 | 50 | 25 | 3 | 2.5 | 35 | 18 | 2 | 1.7 |

50×50×22 | 60 | 30 | 4 | 3 | 43 | 22 | 2.6 | 2 |

75×50×22 | 100 | 50 | 6 | 4 | 71 | 36 | 4 | 2.5 |

100×50×22 | 150 | 75 | 9 | 6 | 106 | 55 | 5.8 | 3.8 |

75×75×22 | 160 | 80 | 10 | 7 | 110 | 60 | 6.5 | 4 |

100×100×22 | 260 | 140 | 14 | 9 | 142 | 72 | 8.6 | 5.5 |

150×150×22 | 500 | 260 | 20 | 13 | 273 | 140 | 12 | 7.8 |

200×200×22 | 850 | 450 | 32 | 20 | 540 | 280 | 19 | 12 |

Gray cast iron: 2.0-4.0 kg/cm²;

Ductile iron: 1.0-2.0 kg/cm²;

Alloy cast iron: 0.5-1.0 kg/cm²;

The filtration capacity indicated in the above table is for 10PPI mesh, and for 20PPI or finer mesh filter plates, the filtration capacity is reduced by about 20% for every 10PPI decrease in mesh size.

7. Filtration effect of molten stone foam ceramic filter plates

Increase process yield by 5-10%;

Reduce casting defect rate by 15-30%;

Increase strength by 5-10%;

Improve the machinability of castings. The application of molten stone foam ceramic filters in casting production effectively filters large debris in the molten metal, adsorbs fine inclusions in the molten metal, reduces the content of gases and harmful elements in the molten metal, improves the microstructure of castings, and improves the mechanical properties of castings. Welcome to inquire.

Keywords:

Learn More Cases

Based on the innovation in the high temperature industry technology field, we constantly explore to solve the needs of high-end high temperature resistant materials and their application fields.